PA11 CF + SLS Printing Explained: Why It’s Different from Regular 3D Printing

Posted by Zac on Jul 24th 2025

Not Your Typical 3D Printing: PA11 CF + SLS Technology

This isn’t the kind of 3D printing you’ve seen on a hobbyist’s desktop.

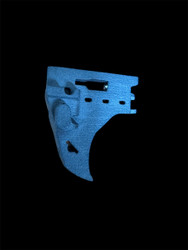

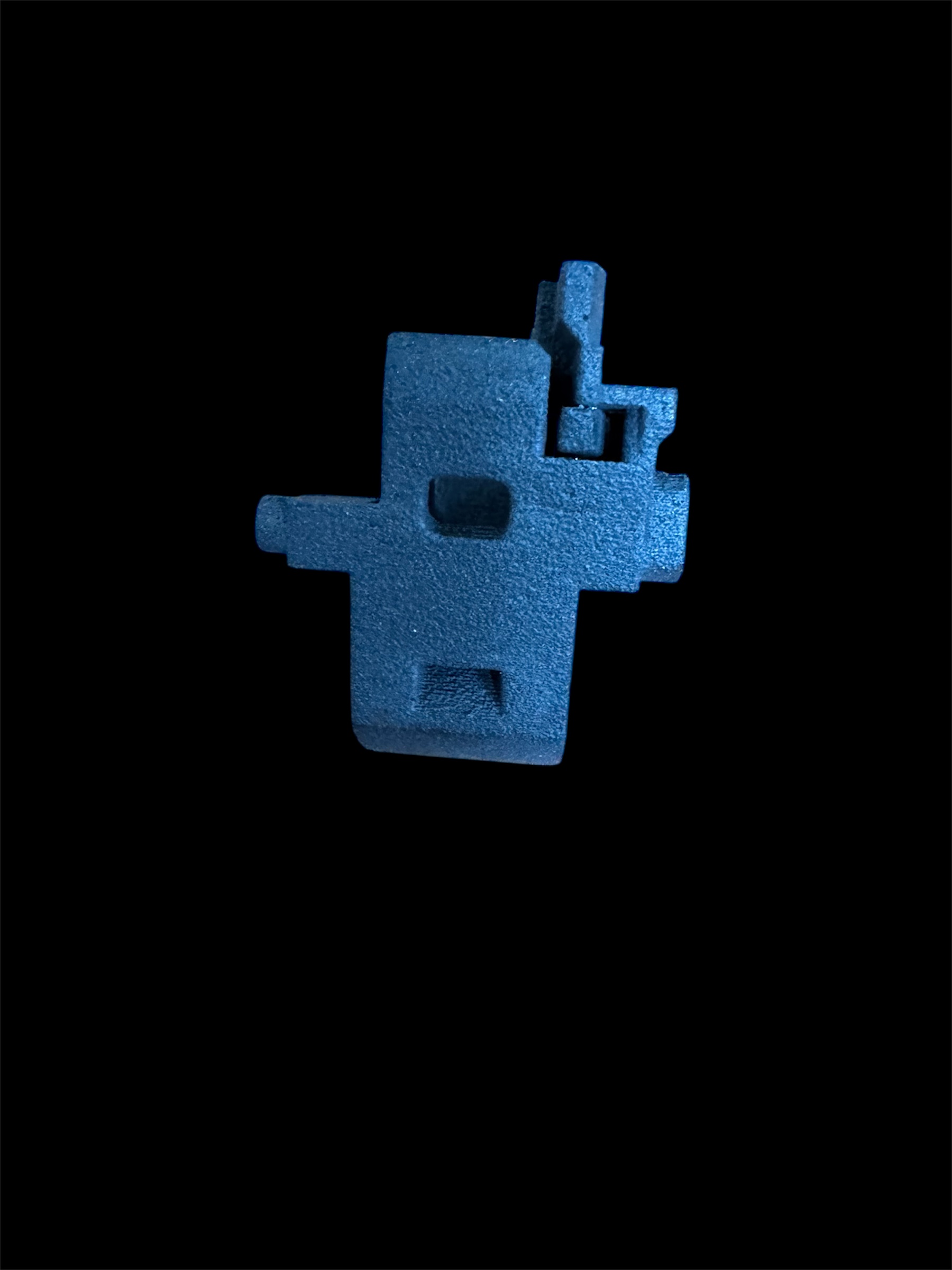

The Us2a Arms GPT‑X trigger housing and magwells are made from PA11 CF (carbon fiber–reinforced nylon) using Selective Laser Sintering (SLS)—a high-end manufacturing process trusted in aerospace, motorsports, and defense.

Unlike typical 3D printing with spools of filament, SLS uses a powerful laser to fuse ultra-strong carbon fiber nylon powder layer by layer, creating parts that rival injection-molded polymer in strength and precision.

That’s why PA11 CF + SLS isn’t just “plastic”—it’s an engineering-grade material and process designed for extreme durability, heat resistance, and accuracy.

GPT‑X housing made from PA11 CF using advanced SLS printing.

PA11 CF + SLS Printing: Why the GPT‑X Trigger Housing & Magwells Are Built for the Future

The Us2a Arms GPT‑X trigger housing and magwells aren’t made with typical injection‑molded polymer. They’re built from PA11 CF (carbon fiber–reinforced polyamide) using Selective Laser Sintering (SLS)—a manufacturing process trusted in aerospace, motorsports, defense, and robotics.

This combination delivers strength, precision, and reliability beyond what traditional polymer parts can offer. To understand why, let’s look at the material and the manufacturing process behind it.

What is PA11 CF?

PA11 CF is a bio-based nylon made from renewable castor oil and reinforced with carbon fibers for enhanced mechanical properties.

Unlike standard firearm polymers, PA11 CF offers:

- High strength and stiffness – comparable to some lightweight metal alloys

- Excellent impact resistance – absorbs force without cracking

- Thermal stability – tolerates high temperatures from extended shooting

- Dimensional stability – minimal warping or shrinkage over time

- Chemical resistance – resists oils, solvents, and harsh gun cleaners

- Sustainability – derived from castor oil, making it a more eco‑friendly option

Slant rear Ruger RXM magwell SLS-printed in PA11 CF carbon fiber nylon.

This is not a basic nylon—it’s an engineering‑grade material used in some of the most demanding industries.

Where PA11 CF is Used

PA11 CF isn’t unique to firearms—it’s trusted in industries where lightweight durability is critical:

Automotive & Motorsports

- High-performance engine components

- Lightweight brackets and supports replacing metal

- Prototypes and testing fixtures

Aerospace & Defense

- UAV and drone components

- Internal aircraft structural parts

- Protective casings for sensitive electronics

Industrial & Robotics

- Wear-resistant gears and moving parts

- Robotic grippers and custom jigs

- High-durability mounts and fixtures

Medical & Prosthetics

- Lightweight, custom prosthetics

- Durable orthotic support structures

Consumer Products

- High-end sports equipment

- Drone frames and RC model parts

- Electronics housings and connectors

If PA11 CF is trusted to keep aircraft components stable in flight and engine parts intact under heat and vibration, it’s more than capable of handling the demands of firearm components.

What is SLS Printing?

SLS (Selective Laser Sintering) is a high-end additive manufacturing process—far beyond typical hobby 3D printing.

Here’s how it works:

- Powder bed preparation – A thin layer of PA11 CF powder is spread across a build platform.

- Laser sintering – A high-powered laser selectively fuses the powder, following the part’s digital model.

- Layer-by-layer construction – The platform lowers and another layer is added, repeating until the part is complete.

- Cooling and post-processing – Once cooled, the part is cleaned, and optional finishing (like bead blasting or dyeing) improves surface texture.

The result is a dense, strong, and highly accurate part—comparable to injection-molded components in mechanical strength.

Why SLS is Ideal for Firearm Parts

SLS printing has unique advantages that directly benefit gun components:

Precision SLS-printed magwell made from PA11 CF carbon fiber nylon.

- High strength and durability – parts rival injection molding in performance

- Excellent heat resistance – ideal for parts exposed to sustained firing heat

- Complex geometries without supports – allows optimized designs that traditional machining can’t achieve

- Material reusability – unused powder is recycled, reducing waste

- Consistency and precision – eliminates weak points from support removal

- Chemical resistance – perfect for exposure to oils and cleaners

This is why SLS is used in aerospace and motorsports for mission-critical parts—and now, it’s being applied to firearms.

Strengths of SLS-Printed PA11 CF Parts

When you combine PA11 CF with SLS printing, you get parts with:

- High tensile strength

- Excellent impact resistance

- Dimensional accuracy and detail

- Thermal stability up to ~190°C (depending on load)

- Minimal warping or shrinkage during printing

The surrounding powder supports the part during printing, so no extra support structures are needed—meaning the finished piece is uniformly strong with no weak spots.

Regular 3D Printing vs. SLS PA11 CF

| Feature | Regular Hobby 3D Printing (FDM/PLA/ABS) | SLS Printing with PA11 CF |

|---|---|---|

| Strength | Moderate, weak along layer lines | High, dense, uniform parts |

| Heat Resistance | Low (softens around 60–90°C) | High (~190°C thermal stability) |

| Chemical Resistance | Poor, vulnerable to solvents & oils | Excellent, resists gun cleaners & oils |

| Dimensional Accuracy | Limited, prone to warping | Precise, comparable to injection molding |

| Surface Quality | Visible layer lines, needs post-finish | Smooth, uniform, no support marks |

| Durability | Not ideal for load-bearing parts | Long-lasting, engineering-grade |

| Material Type | Basic plastic filament | Carbon fiber–reinforced nylon |

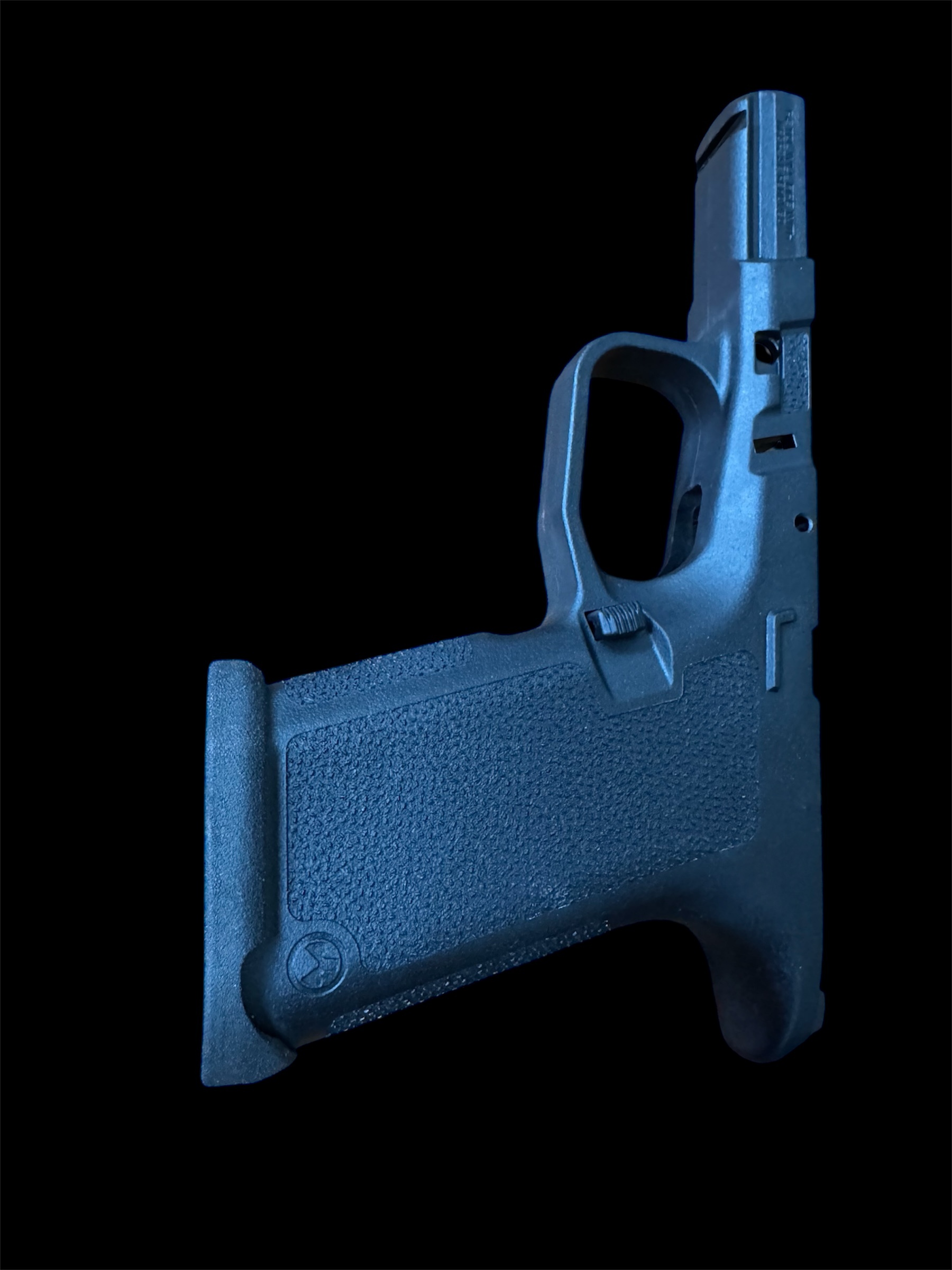

Why We Chose PA11 CF + SLS for the GPT‑X Trigger Housing & Magwells

Factory housings are usually made from standard injection-molded polymer, designed for cost and mass production—not extreme performance or precision fit.

Our GPT‑X trigger housing and magwells deliver advantages OEM polymer can’t match:

- Higher stiffness → keeps trigger geometry precise for a crisper feel

- Superior heat resistance → won’t soften under sustained firing

- Better chemical resistance → unaffected by solvents and cleaners

- Longer life → resists creep and wear from long-term use

- Tighter tolerances → SLS printing achieves repeatable precision

- Optimized design freedom → allows more efficient shapes for function and strength

It’s the same technology used in aerospace brackets and UAV components, now applied to a firearm platform.

From Aerospace to Firearms: A Proven Technology

- In automotive, PA11 CF replaces metal to cut weight without sacrificing strength.

- In aerospace, it protects electronics and supports flight-critical structures.

- In defense, it’s used in UAVs and ruggedized mounts for mission-ready gear.

- In medical fields, it’s trusted for prosthetics that must endure daily impact.

If it’s reliable in those extreme conditions, it’s the perfect upgrade for a firearm component that demands durability and precision.

The Result: A Next-Level Firearm Component

The GPT‑X trigger housing and magwells aren’t just aftermarket parts. They’re precision-engineered components built with the same materials and processes trusted in aerospace, motorsports, and defense.

- Lightweight yet stronger than traditional polymer

- Resistant to heat, chemicals, and wear

- Manufactured with repeatable precision using SLS technology

When you choose the GPT‑X housing or magwell, you’re getting a firearm upgrade built with cutting-edge engineering materials—not just another molded plastic part.

Ready to Upgrade?

Us2a Arms GPT‑X Trigger Housing & Magwells

- Built from PA11 CF (Carbon Fiber Reinforced Polyamide)

- Manufactured using Selective Laser Sintering (SLS)

- Designed for superior strength, fit, and longevity

Shop Ruger RXM Magwell – Slant Rear

Shop Ruger RXM Magwell – Flat Rear

Bring aerospace-level material science to your firearm.